LEARNING CENTER

Welcome to our Learning Center! Dive into a wealth of knowledge about MAINTAIN-V, where we provide insights and resources on various topics. From periodic maintenance to understanding the differences between EAM and CMMS, our Learning Center covers essential information to enhance your understanding and optimize your operations. Explore our curated content to gain valuable insights and stay informed about the latest trends and practices in the industry.

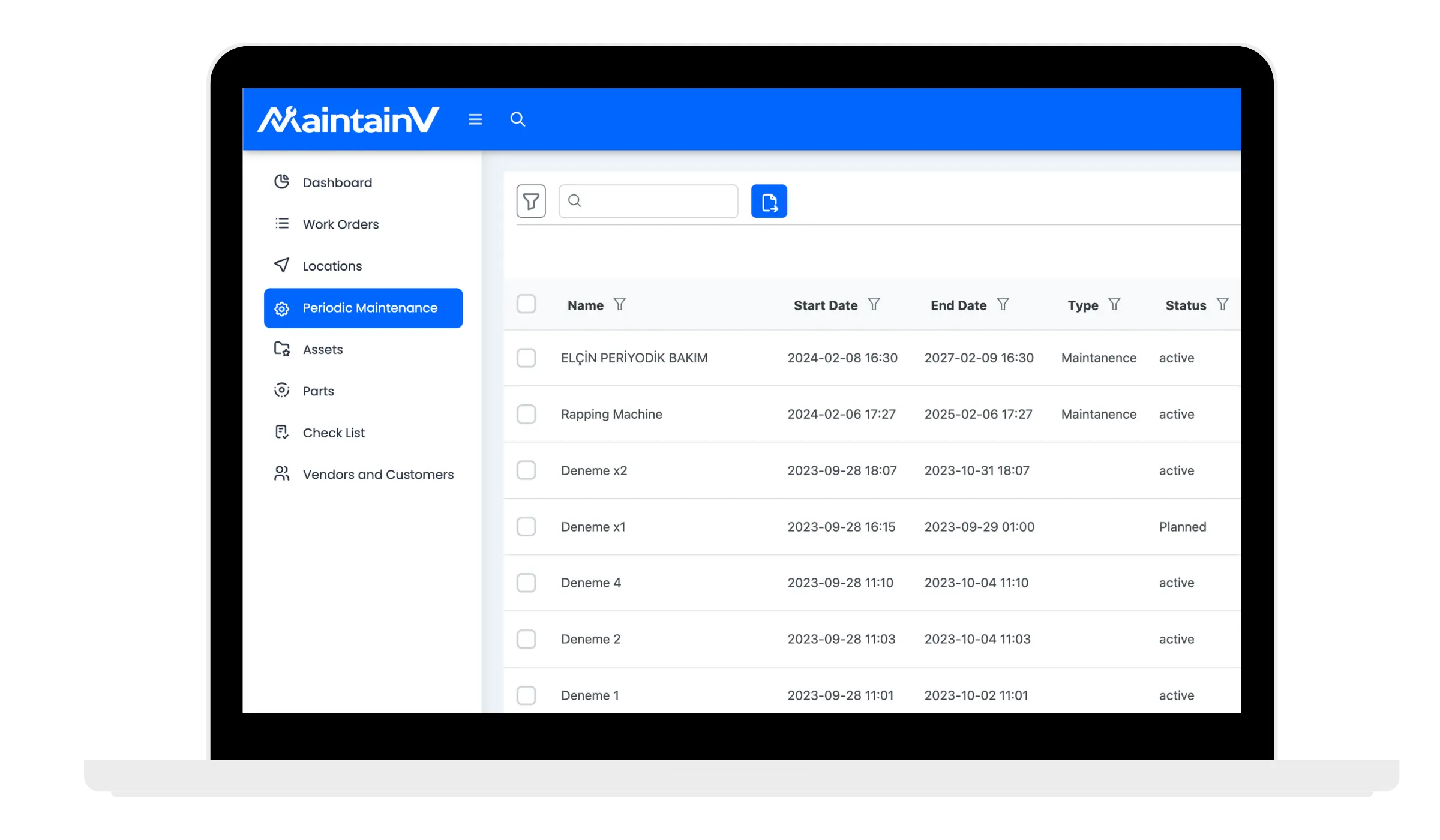

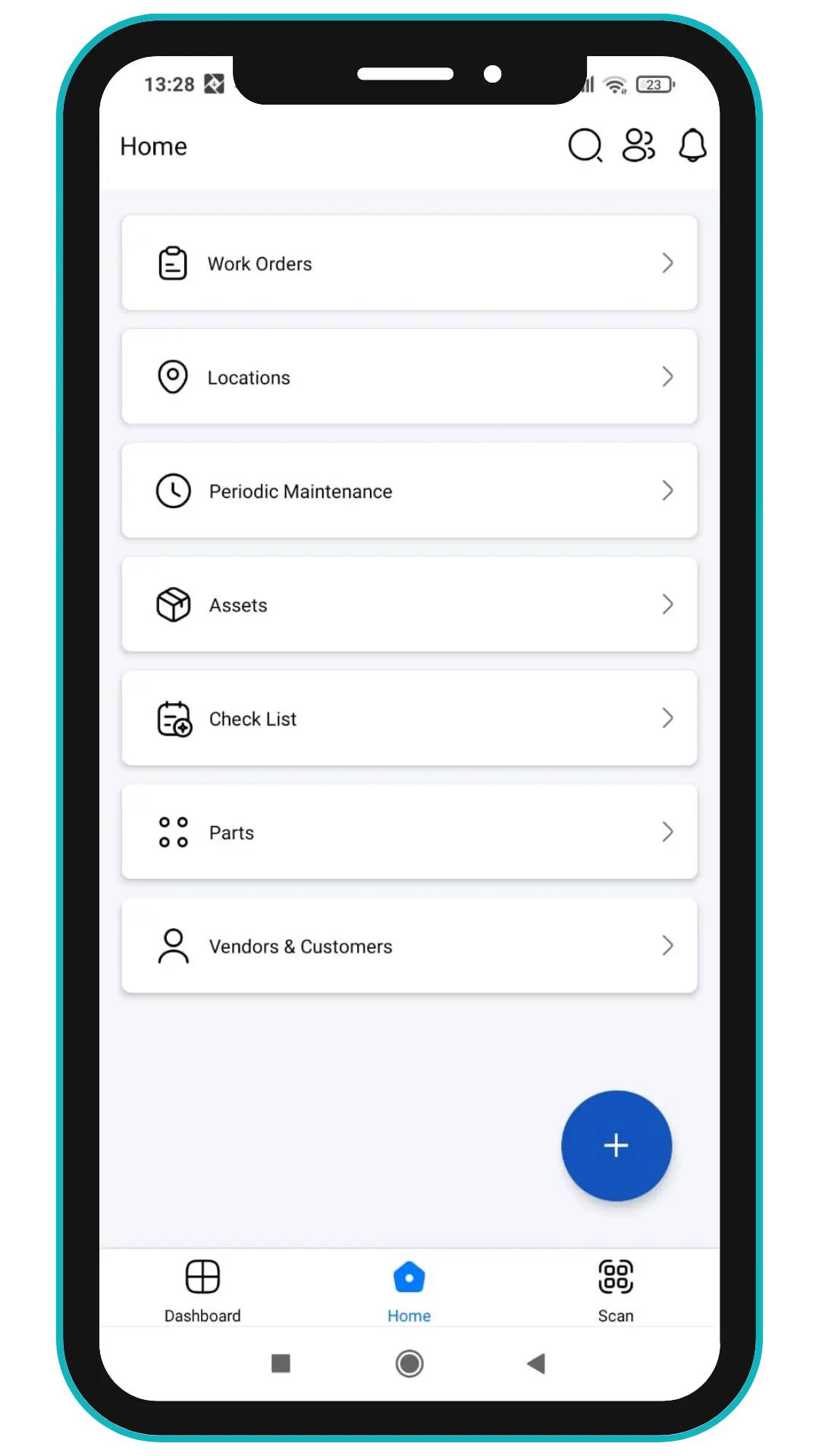

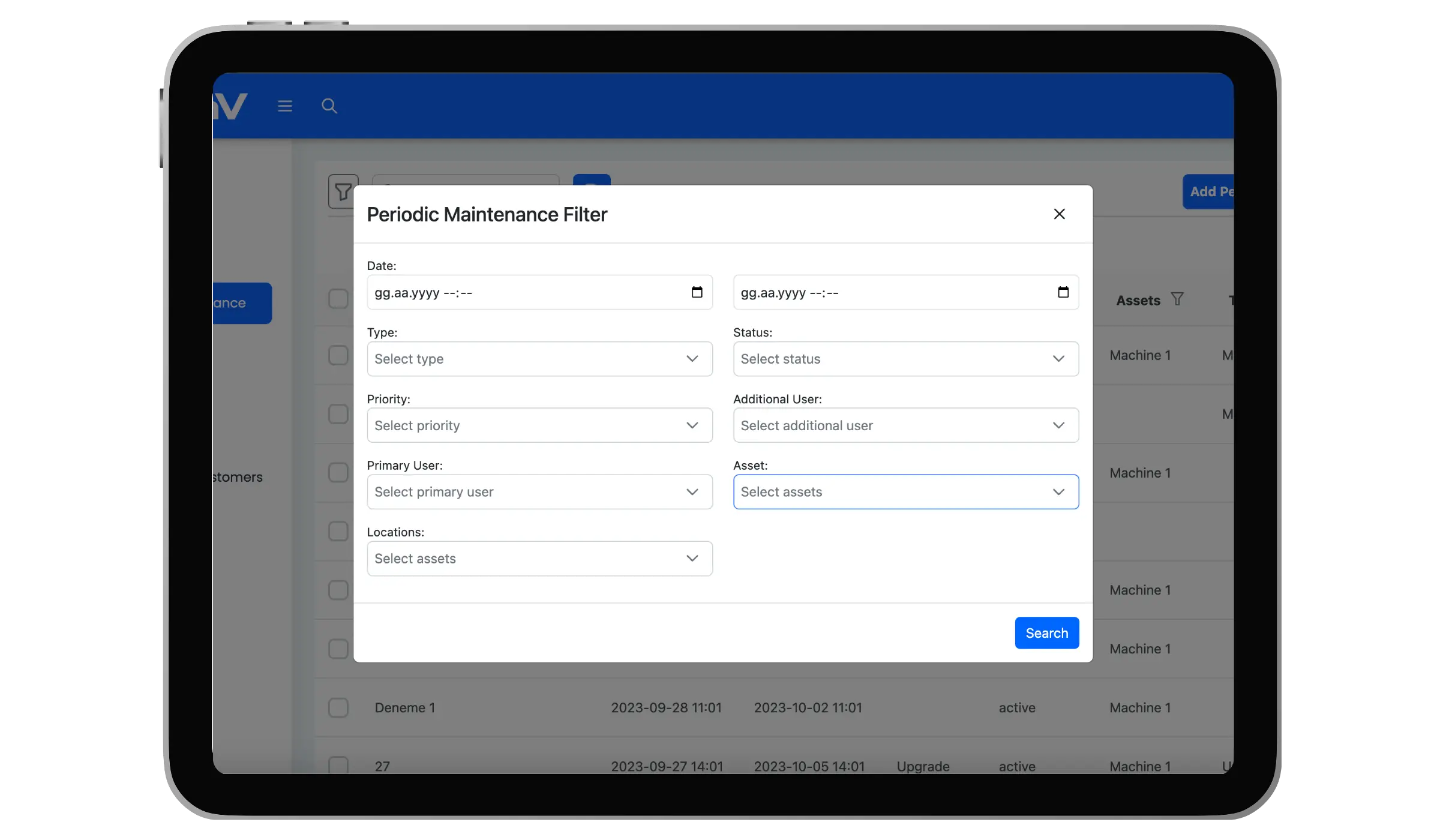

PERIODIC MAINTENANCE

Periodic maintenance is an ongoing process that helps extend the life of any piece of equipment. It involves inspecting and servicing machinery or equipment on a regular schedule to ensure it remains in peak performance. If you operate a manufacturing plant, warehouse, or another industrial site, periodic maintenance can prevent small issues from turning into major problems.

It’s also an excellent way to reduce your operating costs by reducing the risk of unplanned downtime and repairs. At first glance, periodic maintenance appears like an unnecessary cost -- why not just replace broken parts when they break? Well, because those small repairs add up fast!

Luckily, once you understand the benefits of periodic maintenance, it’s fairly easy to implement it in your own business.

Why is periodic maintenance Important?

Periodic maintenance is a system that helps you manage replacement parts, repairs, and other maintenance activities. If you have a machine or piece of equipment that needs periodic maintenance, that means you need to perform certain tasks regularly to keep it in good working condition.

Periodic maintenance is important because if you don’t perform it on a regular basis, certain parts could break and cause your entire operation to shut down. Periodic maintenance helps to extend the life of your equipment and reduce breakdowns by identifying potential problems before they escalate into full-blown failures

What is a periodic maintenance procedure plan?

A periodic maintenance procedure plan is a document that outlines the maintenance activities and procedures for a given piece of equipment or machinery. It includes information like what types of parts are included in the scheduled maintenance, how often each part should be checked, and what specific testing or measurements should be completed. A periodic maintenance procedure plan should be created for every piece of equipment in your operation that requires periodic maintenance. With the right plan in place, you’ll know exactly when and what maintenance tasks need to be performed.

What is the difference between periodic and preventive maintenance?

Periodic maintenance is a set schedule for inspection and repair of a machine or piece of equipment. Preventive maintenance is a proactive strategy for keeping machines and equipment in good working condition.Some of the main differences include:

- Preventative maintenance is less frequent than periodic maintenance

- Periodic maintenance is time-based (scheduled) maintenance activity whereas preventative maintenance activity depends on the condition of the asset

- The important thing to remember is that both of these activities are used to keep machines and equipment in good working order. The key difference is that periodic maintenance is used to address issues as they arise, whereas preventive maintenance acts as a preventative measure to keep machines in good working order.

WHAT İS THE DİFFERENCE BETWEEN EAM AND CMMS?

At an essential level, enterprise asset management (EAM) software operates like a more advanced, larger-scare computer maintenance management system (CMMS). In fact, the development of EAM systems followed many years after the original CMMS solutions came on the market.

Consider this metaphor. A CMMS was originally kind of like heartbeat monitoring equipment. It keeps an eye on the “pulse” of the factory’s assets, alerting maintenance technicians when they need to fix something, or perform preventive maintenance. Once a facility is too large for a CMMS to adequately cover every asset, an EAM becomes the right choice because of the sheer amount of factors that need to be tracked.

In this comparison, the traditional EAM would be like a computer system that tracks every vital sign, medication, and body fluctuation of a patient from their entry to the hospital to the moment they leave. So while a CMMS gives you a good idea of how your assets are doing right this moment and help you plan for the future, an EAM tracks the entire lifecycle of every piece of equipment you own, from the second it’s purchased to the moment it becomes scrap.

In addition to being larger in scope, EAM systems have additional features outside of preventive maintenance, including financial audits, lockout tagout procedures, and in-depth maintenance records and histories for decommissioned equipment.

Today, EAM and CMMS solutions share many of the same features and sometimes overlap in terms of capabilities. However, it’s important to understand the differences that remain, the advantages and disadvantages of each, and which solution is best for your company.

A Historical Perspective

It’s helpful to look at how both EAM and CMMS came into existence, along with the development of other related technologies, such as enterprise resource planning (ERP) solutions, network computing, and the internet to better understand where we are today. Some of these developments happened one after another, while others occurred simultaneously in different industries.